Various frame fixing options are available. The purpose of the fixing is to enable connection between the pressed metal door frame and the wall. The type of fixing selected will depend on the type of your wall, how you intend to finish the junction between the wall and the frame and the way in which you would prefer to install the frame into or onto the wall.

The list below details the standard fixing options available along with a short overview of where they would be used.

Standard Fixing Options

Wire Tie

Suitable for throats up to 150mm a wire tie is a ‘V’ shaped tie used to clip into the back of the frame and protrude past the frame for alignment between courses of bricks during the construction of the wall. Wire ties are supplied loose in a standard pack of 10. Wire Ties are also available for sale as separate item. Buy online

Block Tie

Suitable for throats over 150mm a block tie is a ‘U’ shaped tie used to clip into the back of the frame and protrude past the frame for alignment between courses of blocks during the construction of the wall. Block ties are supplied loose in a standard pack of 10. Block Ties are also available for sale as separate item. Buy Online

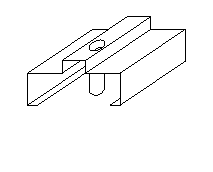

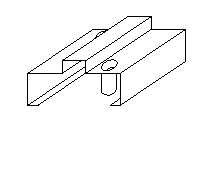

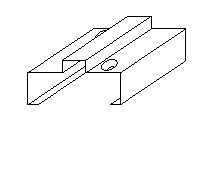

Stud Clips

Stud clips are designed to clip into the back of the frame and protrude past the frame for anchoring on the wall stud. The stud clip is sized to accommodate the thickness of the wall sheeting to allow sufficient space between the wall channel and the frame return allowing the wall sheeting to be slid into the back of the frame.

Stud clips come in standard sizes of 6mm, 10mm, 13mm and 16mm. Other sizes can be manufactured on request to suit your wall linings thickness or multiple wall linings. Stud clips are supplied loose in a standard pack of 16.

If required stud clips can be welded to the frame but this is not common practice. If you are considering having stud clips welded to the frame consider strap, partition or S2000 fixing as an alternate fixing method.

Stud clips are not suitable for retrofit frames and a frame fixing for some brands of fire doors. Please check with your fire door supplier if stud clips are an approved method for fixing of the frame to the fire wall. Alternatives fixing methods for fire rated frames include strap, partition or S2000 fixing. Stud Clips are also available for sale as separate item. Buy Online 6mm 10mm 13mm 16mm

Strap Fixing

Manufactured in 1.4mm Zincanneal, straps are welded to rebates under the stop section of the frame which allows for the screwing through the wall channel or stud into the strap fixed to the back section of the frame. As with stud clips this fixing method allows for the wall sheeting to be slid into the back of the frame with the size of the throat (the opening at the back of the frame between the returns) calculated to accommodate the total overall wall thickness.

Strap fixing is suitable for non rated and fire rated walls and for frames which are being installed as the wall is constructed. Strap fixing is not a suitable fixing alternative for retrofit frames.

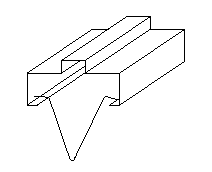

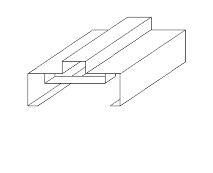

Partition

Forming part of the frame profile a partition fixing is an extended fin off the back of the frame with a throat dimension sized to accommodate the size of the wall channel or stud.

This fixing method requires the finishing of the wall sheet junction to the edge of the frame as the wall sheet does not slide into the back of the frame; it is installed butted to the edge of the frame.

Partition fixing is suitable for installation in walls during construction for both non rated and fire rated wall types but is not a suitable fixing method for retrofit frames.

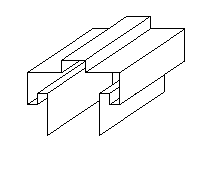

Bracing Strap

Manufactured in 1.4mm Zincanneal, bracing straps are welded between the returns of the frame across the throat which allows for the screwing of the wall channel or stud into the bracing strap. Unlike stud clips and strap fixing this fixing method provides for the wall sheeting to be finished flush with the face of the frame rather than sliding into the back of the frame and would require the finishing of the wall sheet junction to the edge of the frame.

Bracing straps are suitable for non rated and fire rated walls and for frames which are being installed as the wall is constructed.

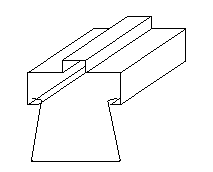

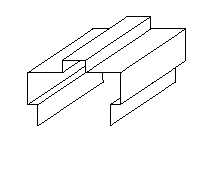

S2000

Forming part of the frame profile S2000 fixing, also referred to as a New Generation Frame, is an extended fin off the back of the frame with a throat dimension sized to accommodate the size of the wall channel or stud and a ‘U’ section (or sheet alcove) extending into the back of the frame sized to accommodate the wall sheeting.

S2000 fixing is suitable for installation in walls during construction for both non rated and fire rated wall types but is not a suitable fixing method for retrofit frames.

Countersunk

Countersunk fixings are dimples formed into the frame during manufacture and are suitable for fixing off the frame to an existing opening with an expanding fixing such as a dynabolt or similar. The hole for the fixing is 12mm to suit a M10 dynabolt or similar. A smaller hole is available if required.

The countersunk holes can be either centred on the frame or staggered to accommodate installations where the wall includes a cavity between two wall sections (e.g. double brick construction).

Countersunk fixing is not suitable for new installations and is designed to allow the frame to be fixed to an existing wall. If you are building into a brick, block or concrete wall consider wire ties or block ties as alternative fixing method.

.png)

Tube Fixing

Tube fixings are dimples installed into the stile of the frame with a tube spacer welded to the back of the dimple suitable for fixing off the frame to an existing opening with an expanding fixing such as a dynabolt or similar.

The tube welded to the back of the hole protects the hole from being blocked during the back filling of the frame (required for fire rated applications) and also provides a spacer to ensure the frame does not pull in when installing the dynabolt fixing. The hole for the fixing is 12mm to suit a M10 dynabolt. An 8mm hole is available if required.

The tube fixing holes can be either centred on the frame or staggered to accommodate installations where the wall includes a cavity between two wall sections (e.g. double brick construction) or where the overall width of the frame requires staggered fixings to ensure a firm connection between the frame and the wall.

Tube fixing is not suitable for new installations and is designed to allow the frame to be fixed to an existing wall. If you are building into a brick, block or concrete wall consider wire ties or block ties as alternative fixing method.